Objectives

WIDEM in short

The economic efficiency and competitiveness of the rail transportation mode depends on safety, availability and maintenance of its individual highly loaded structure components such as railway wheelsets.

The WIDEM project aims to improve efficiency and competitiveness through a fundamental re-examination of wheelset design, which in turn will facilitate improved maintenance practices.

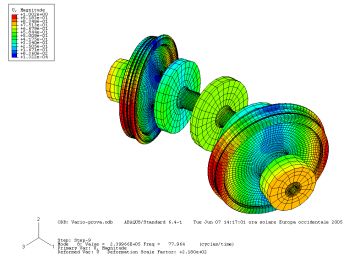

Combining inputs from reliable service measurement of wheel-rail forces carried out by means of an innovative instrumented wheelset and extensive assessment of actual material properties, an original endurance strength design concept will be developed and validated through a comprehensive testing programme on full scale wheelset prototypes.

A flexible numerical tool is also proposed as an upgrading of existing knowledge.

Additionally, the project will develop and evaluate alternative NDT (non-destructive testing) techniques that allow a greatly increased detection probability and a size estimation of cracks to set up a schedule for NDT periodicity inspection.

The research work will lead to the definition of wheelset design procedures and maintenance methods to be implemented into existing standards for quick and easy optimisation of the process.

State of the art

Contemporary wheelset design is based on many years of practical railway experience; designers will often use established design cases based on custom and practice that are not explicitly linked to real loadings. At the same time existing Standards do not rigorously address the procedures of how to determine materials properties to be used in the design, but still use empirical methods based on the experience of traditional materials.

This subjective approach is not wrong; its success is demonstrated by the outstanding safety record of rail systems. The limitation with this design methodology is that wheel and axle design and the scheme of associated maintenance and inspection operations is pessimistic and cannot be optimised.

This situation generates limitations to the train set performance.

Wheelset mass is higher than necessary because little is known of loads that wheels and axles actually endure, thus calling for conservatism on the part of the designer. Additionally, this high level of wheelset mass causes high wear on running gear elements. Also a high level of maintenance is necessary to inspect the wheelset using NDT techniques. The track also deteriorates at a higher rate, requiring further maintenance.

Design requirements for new running gear tend to be reduction of weight and LCC (Life Cycle Cost) for a fixed level of safety. The former, needed to reduce the level of dynamic loads, is achieved through a wheelset geometry optimisation process; the latter by increasing life length through full exploitation of materials which are used and optimised nondestructive inspection practices.

It is clear that these requirements will be fully implemented only if future railway Standards will make use of innovative approaches based on a radically improved evaluation of actual wheelset material damage mechanisms and dynamic load inputs for a consequent measurable increase of reliability.

It is also clear that wheelset design, LCC and maintenance practices are highly interconnected and that should be treated together to achieve the expected benefits.

Better wheelset design, informed by good quality information about real wheelset loads and verified material properties offers the potential to break into this loop through optimised, lightweight wheelset design with scientifically determined NDT inspection intervals.

Project objectives

The main objective of the WIDEM project is to push the boundaries of wheelset component design through the application of advanced design concepts and extension of maintenance intervals.

The project vision will be implemented through interfaced phases of work with the following technical research and development objectives:

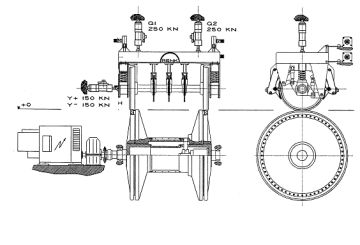

- Analysis of the interaction between wheel and rail in order to have a good understanding of the magnitudes of the forces transmitted between the two components.

The project will deliver through this an innovative instrumented wheelset for loads measurement to radically improve knowledge of real force inputs to the wheelset design.

Innovation can be found in both electronic characteristics and calibration process of the instrumented wheelset.

The acquisition system will offer modularity, higher speed and resolution, high performance multi-channel wireless connectivity and self recharging capability.

Differently from the current static practice, calibration of instrumented wheelset is carried out on a full scale dynamic test rig which enables accurate assessment of the measurement system.

Two instrumented wheelsets will then equip the bogies of a tilting trainset and a 33 tonnes axle load freight car respectively and run across European railways network for service measurement of wheel-rail forces and further data processing strategy.

- The development and validation of a flexible multi-body numerical tool in the framework of the new wheelset design methodology, is foreseen to determine loads as a function of specific vehicle service profile and to cover the generality of cases when direct measurement activities are not possible.

The simulation advancement, based on existing knowledge, accounts for high frequency dynamic train/track interaction (S & C, wheel-rail defects, irregularities) to capture rapid transient loads variations in a reliable way.

- The other horn of the dilemma, which presents a major challenge for wheelset manufactures, is the need to exploit all the performance reserves of the material which are used and overcome the existing constraints which do not encourage metallurgy research.

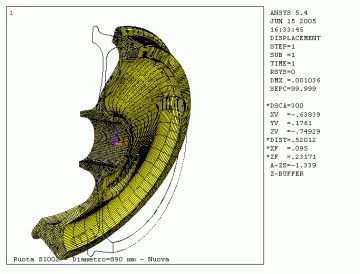

The above reflects a main project objective: define a thorough procedure for assessing actual material properties carried out by an exhaustive full scale testing program, mostly focused on classical and fretting fatigue.

The project will have to integrate recent developments in areas such as rolling contact fatigue performed in ongoing European research projects.

The integration of measured load spectra with the experimental material data, including fracture failure and inspection considerations, will finalise the key objective of the project: provide a new endurance strength design concept for railway wheelset.

|

Site programming and design by Adam Foster Web Engineering |